Introduction

Stickers have long been an effective tool for communication and branding. From promoting businesses to personalizing products, they have a wide range of applications. In the B2B (business-to-business) industry, custom self-adhesive stickers have emerged as a popular choice to enhance brand visibility, streamline operations, and foster customer engagement. This article examines the multi-step process involved in creating custom self-adhesive stickers for B2B buyers. By delving into each stage, from concept development to production, we will explore the intricate details that contribute to an exceptional final product.

Custom self-adhesive stickers play a vital role in B2B marketing strategies. They serve as a cost-effective medium to amplify brand presence, differentiate products, and communicate key messages. According to a survey conducted by HubSpot, 60% of consumers find stickers valuable in establishing brand recall. Moreover, a study by 3M showed that promotional stickers help increase sales and customer loyalty, with 62% of consumers stating that they are more likely to purchase from a brand that offers stickers.

Step 1: Concept Development: The process of creating custom self-adhesive stickers begins with concept development. It entails identifying the purpose and objectives of the sticker, researching the target audience and market trends, and collaborating closely with designers. Only by understanding these factors can businesses create stickers that resonate with their intended recipients. For instance, a B2B buyer looking to promote eco-friendly practices might opt for stickers made from recycled materials or with designs that emphasize sustainability.

Step 2: Design and Prototyping: The next stage involves bringing the concept to life through digital design and prototyping. Experienced graphic designers utilize specialized software and tools to create visually compelling artwork that aligns with branding guidelines and target audience preferences. Prototypes are crucial for receiving client feedback, allowing for fine-tuning before proceeding to the manufacturing stage. This iterative approach ensures that the final product meets the desired aesthetic and functional requirements.

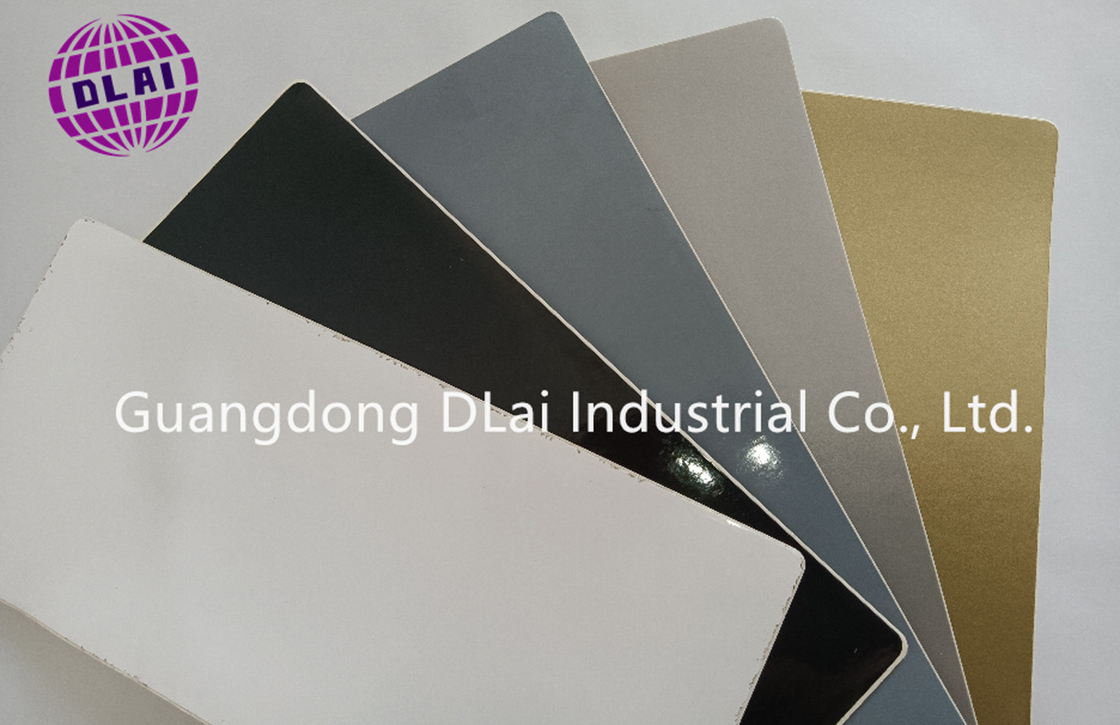

Step 3: Material Selection and Printing: Choosing the right material for custom self-adhesive stickers contributes significantly to their longevity and effectiveness. Factors such as durability, adhesiveness, and resistance to environmental conditions are taken into consideration. For example, in harsh outdoor environments, stickers made from weather-resistant vinyl materials are preferred. Collaborating with printing companies or utilizing in-house printing facilities is essential for achieving top-quality prints. Digital printing, for instance, offers the advantage of customization and quick turnaround times, making it particularly valuable for B2B buyers.

Step 4: Die-Cutting and Finishing: To achieve precise and uniform shapes, the sticker must undergo die-cutting processes. This step involves using specialized equipment to cut the stickers into specific forms, delivering a professional and aesthetically pleasing look. At the same time, various finishing options, such as gloss, matte, or textured finishes, may be added to enhance the overall appeal. In some cases, additional embellishments like foiling or embossing can be incorporated to elevate the visual impact of the sticker.

Step 5: Quality Assurance and Testing: Before the stickers are ready for market, a rigorous quality assurance and testing process is essential. It involves inspecting the final product to ensure that print quality, color accuracy, and adhesive strength meet the highest standards. Compliance with industry regulations is crucial, especially for specialized applications such as food labeling or medical device identification. Testimonials and case studies from satisfied B2B clients can serve as testament to the effectiveness and reliability of the sticker manufacturing process.

Step 6: Packaging and Delivery: In the last phase of production, custom self-adhesive stickers undergo secure packaging to safeguard their integrity during transit. Depending on the quantity and requirements, stickers can be packaged in rolls, sheets, or individual sets. This careful packing ensures that B2B buyers receive their orders in pristine condition, ready to be utilized for various purposes. Efficient delivery methods with tracking and monitoring systems further streamline the process, allowing businesses to confidently fulfill their clients' requirements.

Conclusion:

Creating custom self-adhesive stickers for B2B buyers is a meticulous process that incorporates multiple steps, from initial concept development to final production. These stickers have proven to be an indispensable tool for businesses seeking to enhance brand visibility, differentiate products, and establish a lasting impression on customers. By carefully considering factors such as design, printing materials, and finishes, B2B buyers can obtain high-quality stickers that fulfill their marketing objectives. With the right approach, custom self-adhesive stickers become more than just labels; they become an integral part of a successful branding strategy, unlocking new opportunities for engagement and growth.

As a TOP3 company in the self-adhesive manufacturer industry, we mainly produce self-adhesive raw materials. We also print various high-quality self-adhesive labels for liquor, cosmetics/skin care product self-adhesive labels, red wine self-adhesive labels, and foreign wine. For stickers, we can provide you with various styles of stickers as long as you need or imagine them. We can also design and print the specified styles for you.

Donglai Company has always adhered to the concept of customer first and product quality first. Looking forward to your cooperation!

Feel free to contact us anytime! We're here to help and would love to hear from you.

Adress: 101, No.6, Limin Street, Dalong Village, Shiji Town, Panyu District, Guangzhou

Whatsapp/Phone: +8613600322525

mail: cherry2525@vip.163.com

Sales Executive

Post time: Oct-23-2023