In the modern packaging and logistics industry, protecting and securing products during transportation and storage is a top priority. One of the most commonly used packaging materials for this purpose is stretch film, also known as stretch wrap. Stretch film is a highly stretchable plastic film that tightly wraps around products to keep them secure, stable, and protected from dust, moisture, and damage.

Stretch film plays a crucial role in supply chains worldwide, ensuring that goods remain intact from warehouses to their final destinations. Whether used in pallet wrapping, product bundling, or industrial packaging, stretch film offers a cost-effective and efficient solution for securing loads.

Understanding Stretch Film

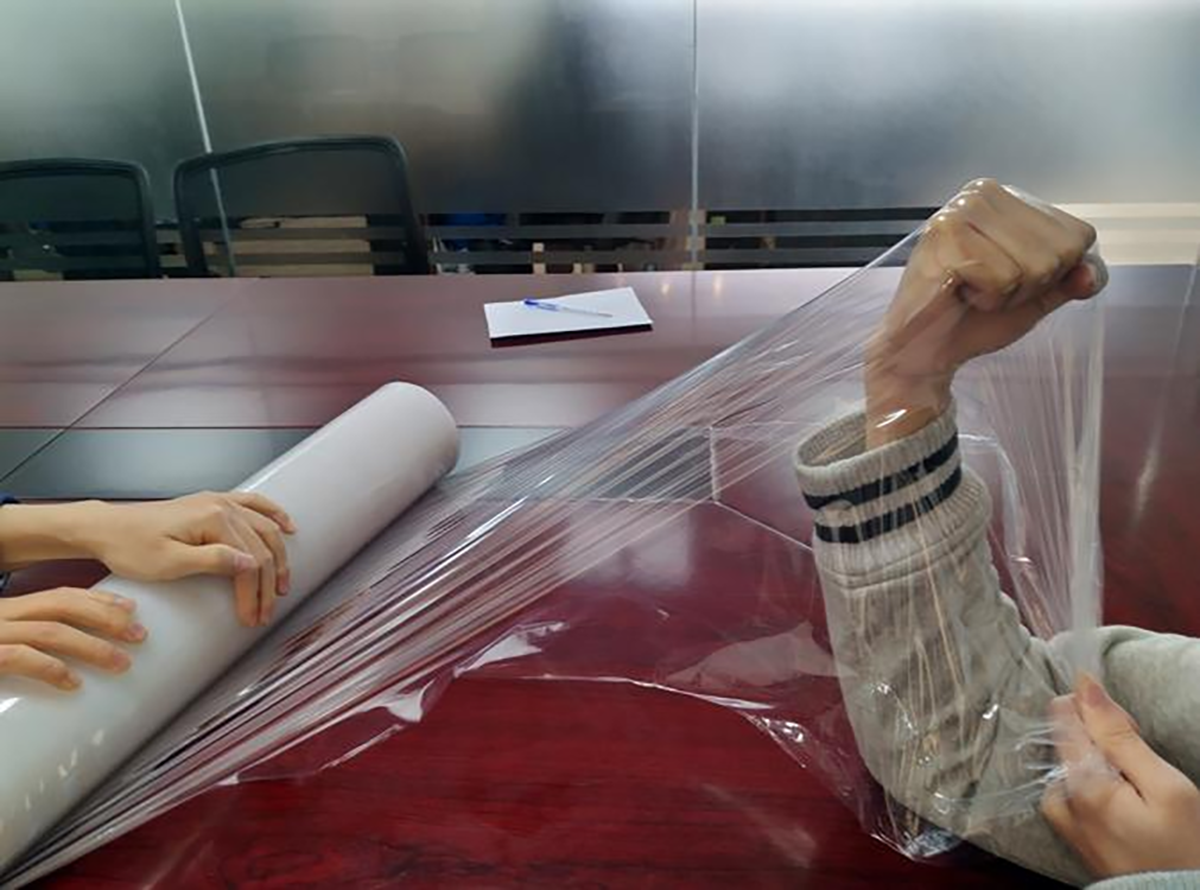

Stretch film is a thin plastic wrap made primarily from polyethylene (PE) resins, specifically linear low-density polyethylene (LLDPE). It is designed to stretch and cling to itself, creating a tight seal around the packaged goods without the need for adhesives or tapes. The elasticity of the film allows it to conform to different shapes and sizes, providing firm load stability while reducing material waste.

Stretch film is commonly applied using manual hand-wrapping techniques or automatic stretch wrapping machines, depending on the scale of packaging operations.

Types of Stretch Film

Stretch film comes in various types, each designed for specific applications and load requirements. The most common types include:

1. Hand Stretch Film

Hand stretch film is designed for manual wrapping and is typically used in small-scale packaging operations or low-volume shipping. It is easy to use and provides excellent protection for light to medium-duty applications.

2. Machine Stretch Film

Machine stretch film is used with automated stretch wrapping machines, offering higher efficiency and consistency in securing pallet loads. It is ideal for high-volume packaging operations in warehouses, distribution centers, and manufacturing plants.

3. Pre-Stretched Film

Pre-stretched film is pre-stretched during the manufacturing process, reducing the effort needed to apply it manually. It offers better load stability, reduced material consumption, and cost savings while maintaining high strength.

4. Cast Stretch Film

Cast stretch film is produced using a cast extrusion process, resulting in a clear, glossy, and quiet film. It provides excellent tear resistance and smooth unwinding, making it easy to use in both manual and machine applications.

5. Blown Stretch Film

Blown stretch film is manufactured using a blown extrusion process, making it stronger, more durable, and resistant to punctures. It is commonly used for wrapping irregularly shaped or sharp-edged loads.

6. UVI Stretch Film (UV-Resistant)

UVI (Ultraviolet Inhibitor) stretch film is specially formulated to protect products from UV exposure, making it ideal for outdoor storage and transportation.

7. Colored and Printed Stretch Film

Colored stretch film is used for product identification, branding, or security to prevent tampering. Printed stretch films can also include company logos or handling instructions.

Key Benefits of Using Stretch Film

✔ Load Stability – Stretch film tightly secures palletized goods, preventing them from shifting or falling during transportation.

✔ Cost-Effective – It is a lightweight and economical packaging solution compared to strapping or shrink wrapping.

✔ Protection from Dust, Moisture, and Contamination – Stretch film provides a protective barrier against dirt, humidity, and external contaminants.

✔ Improved Inventory Control – Clear stretch film allows for easy identification of packaged goods.

✔ Eco-Friendly Options – Many stretch films are recyclable, contributing to sustainable packaging solutions.

Applications of Stretch Film

Stretch film is widely used across multiple industries, including:

◆ Logistics & Warehousing – Securing palletized loads for transportation.

◆ Food & Beverage – Wrapping perishable goods for protection.

◆ Manufacturing – Bundling machinery parts and industrial components.

◆ Retail & E-commerce – Packaging consumer goods for delivery.

◆ Construction – Protecting building materials from dust and moisture.

How to Choose the Right Stretch Film?

Selecting the right stretch film depends on several factors:

1.Load Weight & Stability Needs – Heavy or irregular loads require a stronger stretch film (e.g., blown film).

2.Manual vs. Machine Application – Hand stretch film is best for small operations, while machine stretch film improves efficiency for high-volume packaging.

3.Environmental Considerations – UV-resistant films for outdoor storage or eco-friendly options for sustainability.

4.Cost vs. Performance – Choosing the right balance between budget and durability ensures long-term savings.

Conclusion

Stretch film is an essential packaging material for securing goods in transit and storage. With various types available—ranging from hand-applied to machine-wrapped, clear to colored, and pre-stretched to UV-resistant—stretch film offers a versatile, cost-effective, and protective solution for businesses in diverse industries.

By selecting the right stretch film for your specific packaging needs, you can improve load stability, reduce product damage, and optimize supply chain efficiency. As sustainability trends continue to influence the packaging industry, advancements in recyclable and eco-friendly stretch films are set to enhance the way businesses protect and transport their goods.

Would you like to explore high-quality stretch film solutions for your business? Feel free to reach out to packaging suppliers for expert recommendations tailored to your industry needs!

Post time: Mar-07-2025